Silencer

What is it and how does it work

The silencer is used to reduce the noises produced by the gas discharge in the internal combustion engines, in order to respect the

acoustic pollution regulations.

To reduce the sound emission, the silencer generates a backpressure wave which acts in opposition to the gases emission from the

engine cylinders and influences the performance at different engine speeds.

Using long and / or diameter-reduced exhaust system, low engine speeds are favored, where using short and / or large diameter

exhaust systems high engine speeds are favored.

The main silencing techniques are:

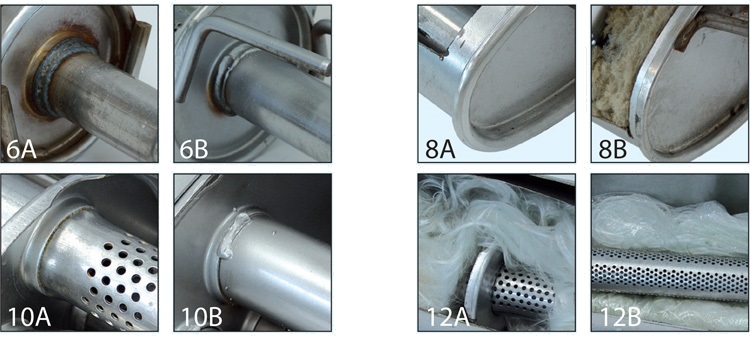

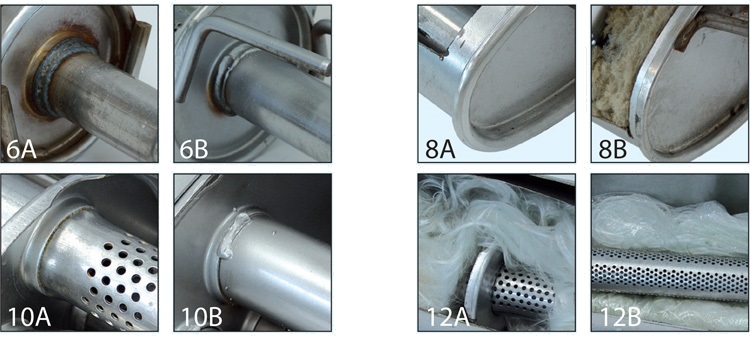

1 absorption: phono-absorbent materials (usually fiber-glass) are used , which are placed inside a hollow cylinder. With this technique

less noise is reduced, but there are better results on all the range of frequencies and lower reduction of power is involved; for

such motivations this is the more used solution in competition engines.

2 reflection: this system is obtained dividing the silencers in several rooms using walls on which sound waves are generated. These

sound waves cancel out each other and, thanks to the phenomena of the interference, the noise is reduced. This technique allows

a higher reduction of the noise, specially at low engine speeds.

3 resonance: this system is obtained using holed pipes which connect several rooms and works like a musical instrument, reducing

and modifying the sound.

4 mixed: this system is obtained using more techniques together, like the combinations absorption-reflection, absorption-resonance

or absorption-reflection-resonance.

MTS respects the solutions adopted by the vehicles manufacturer and supply the aftermarket with products with the same technical

specifications and performances of the original equipment products .

Before the replacement:

A complete check of the whole silencer equipment is necessary:

1 to avoid the substitution of only one part without solving the problem (for example it could seem necessary to substitute the rear

silencer but the reason of the noise could have been due to a manifold problem, by the catalytic converter or by the central silencer).

2 to avoid that the wear or the absence of one or more accessories will damage, in a short time, the new part.

During the replacement:

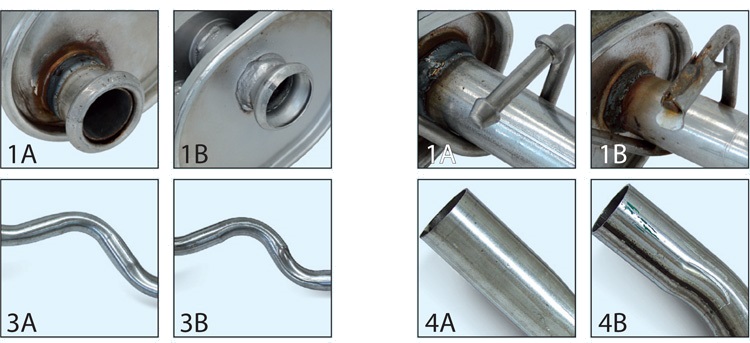

1 if necessary, use new hangers, accessories, gaskets and clamps.

2 put the silencer perfectly in line, to avoid vibrations or abnormal pressures.

3 do not use metal hammers or other hard tools which could damage the silencer.

4 as sealant, if necessary, use the special paste for exhaust systems (which must not substitute the gaskets).

5 carefully verify the new sound emissions to solve immediately eventual problems.

Guarantee:

Are not covered by guarantee all the damages caused by external factors as:

1 silencer braking caused by anomalous vibration or impacts due to accidents or uneven road surfaces.

2 silencer obstruction caused by loss of dross or of phono-absorbent material from the front parts.

3 wrong install with deformation of the connecting pipes or of the hangers.